Well, it was another success. I made another soap for an order the other day and it came together nicely. It did start thickening a bit at the end, so it did not come together as smoothly as the Pink Lavender was, but it still came out rather nicely and I am quite pleased with the results. I think it looks like the clouds moving by across a blue sky.

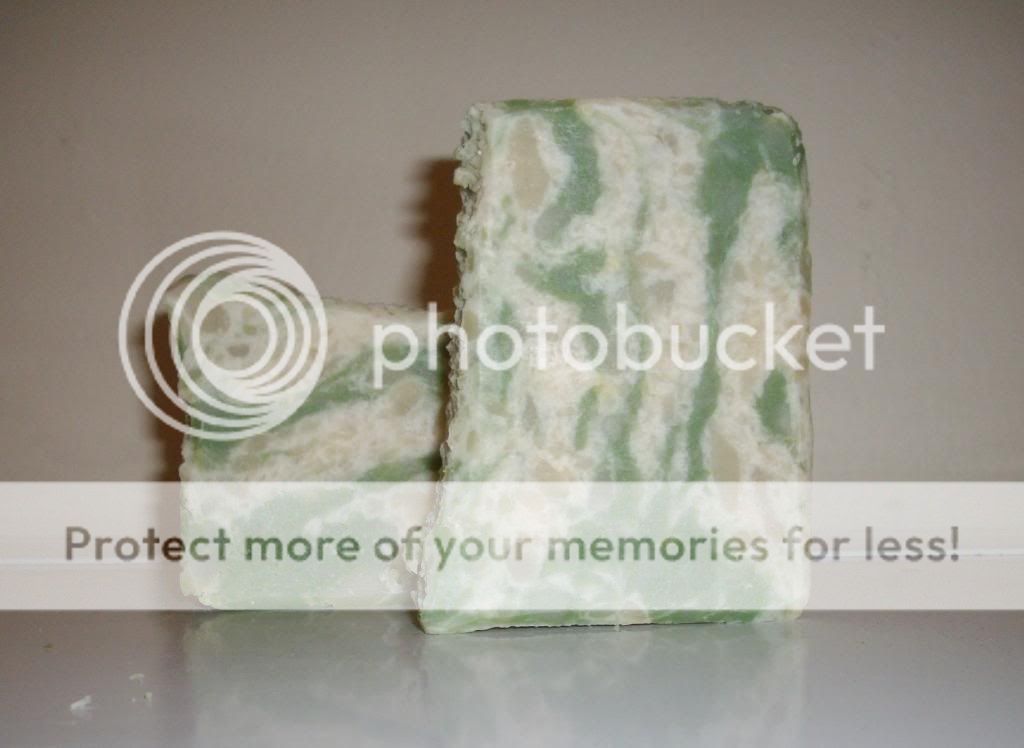

I made another soap today and hope to get it posted in the next couple days. This one is a green and white Swirl scented with Eternity. It came together fairly well also, but more on that when I post the picture ;-)

Wednesday, December 11, 2013

Saturday, December 7, 2013

Success with Pink Lavender!

After a couple of disappointments, I have had another successful soap. I didn't bother posting my blue soap on a stick that turned out looking very similar to the green soap I posted last time, just with blue instead of green. It was a lumpy, icky mess, but it smells nice and is still usable as long as you don't have to look at it ;-)

Anyways, on to the success story... I wanted to work with a scent I was familiar with, so worked with lavender essential oil, and used titanium dioxide to get the white color that was requested and ruby red micah to get the pink color I was aiming at. I used bentonite clay mixed in the essential oil to help hold the scent of the oil in the soap, as essential oils tend to fade a little more than fragrance oils usually do.

My normal soap base came together well, and I was careful not to over mix, coming to a very light trace before adding the fragrance and mixing it a bit more. The bentonite clay made the soap a bit darker and I was worried I would have trouble getting a decent white with it, but I managed to get one of my best whites yet by adding more titanium dioxide than I normally add and mixing well. I managed to still keep a light trace even after mixing everything, which made me very happy, and it was still pretty light and poured evenly into the mold. I think this was a first for me. Most of the time, by the time I pour I have a thick trace and it is pretty hard to pour, so I was happy with this change.

I let it set overnight and in the morning it was still soft, so let it set most of the afternoon as well before I took it out of the mold and cut it. It was still a bit soft when I cut it, and I waited a bit longer then normal to take pictures because of that reason. I think the fact that I had such a light trace was the reason it was so soft. It is otherwise behaving well and has since hardened up fairly well. So, here is my lavender soap in pink in white, as requested by the customer!

Sunday, November 24, 2013

A Big Disappointment

So, I made another soap last week and I am just getting around to posting about it now. Mostly because I was disappointed with it. It started out really well too! I was being very patient and had high hopes for this to be one of my better soaps and well, it was not to be.

So, I mixed my ingredients and instead of waiting to add my fragrance oil until after I had mixed the soap some, I decided to try and add it to the oils and hopefully give myself a little more time with working with the mix so I had one less thing to stir in and hopefully cut down on my chance of stirring too much in the early stages. Well, this was a mistake, it would seem, because as soon as I poured in the lye mixture to the oils, I got soap about the thickness of bread dough.

To say I was not impressed would be an understatement. I work the soap as much as I could and mixed in the colors as best as I was able. The green I was mixing came out mostly okay, but the white left little to be desired. Also, it was crumbling as this point and I shoved it into the mold and hoped for the best.

The top bubbled and it leaked a little oil that it then soaked back in, but it has a sort of crumbly texture to it. It does pass the zap test, so does not appear to be lye heavy, just the reaction from the fragrance oil did weird things to it. To top it off, when I cut it, I could not get things lined up right and my bars are all uneven. This batch was supposed to be used as a gift, but it is not going anywhere.

I am very frustrated. As a note, while I was writing this, I worked on another batch of soap and added the fragrance oil later. The fragrance oil was a different oil from the same company, but it did the same thing. I will unmold that one tomorrow and see if it came out any better then this one, but it is not looking good right now.

So, I mixed my ingredients and instead of waiting to add my fragrance oil until after I had mixed the soap some, I decided to try and add it to the oils and hopefully give myself a little more time with working with the mix so I had one less thing to stir in and hopefully cut down on my chance of stirring too much in the early stages. Well, this was a mistake, it would seem, because as soon as I poured in the lye mixture to the oils, I got soap about the thickness of bread dough.

To say I was not impressed would be an understatement. I work the soap as much as I could and mixed in the colors as best as I was able. The green I was mixing came out mostly okay, but the white left little to be desired. Also, it was crumbling as this point and I shoved it into the mold and hoped for the best.

The top bubbled and it leaked a little oil that it then soaked back in, but it has a sort of crumbly texture to it. It does pass the zap test, so does not appear to be lye heavy, just the reaction from the fragrance oil did weird things to it. To top it off, when I cut it, I could not get things lined up right and my bars are all uneven. This batch was supposed to be used as a gift, but it is not going anywhere.

Sunday, November 17, 2013

Back After a Long Hiatus

Yes, I am back making soap again! It was a long, hot summer, followed by a move, that left me a bit discombobulated, but I am back and making soap again. Over the summer, the old apartment was way too hot to contemplate making soap and the AC unit for the apartment was not worth turning on as it did little to nothing to alleviate the heat. The new apartment actually has cross ventilation, so it should be cooler during the summer.

Anyways, I have an order for four soaps for Christmas, and also am trying to get Yule in order for friends for the season, so I am madly trying to make soaps. I made one yesterday, which was my first soap in a long time, and all things considered, it came out fairly well. I used a dupe of Axe Voodoo fragrance and made the white with yellow swirled.

As usual, it thickened faster than I would have liked and by the end, I was dealing with a pudding like consistency of soap, and I did not get quite the shade of yellow that I would have liked. Overall, I am pretty happy with it still, and I hope that the person receiving it will like it as well.

Anyways, I have an order for four soaps for Christmas, and also am trying to get Yule in order for friends for the season, so I am madly trying to make soaps. I made one yesterday, which was my first soap in a long time, and all things considered, it came out fairly well. I used a dupe of Axe Voodoo fragrance and made the white with yellow swirled.

As usual, it thickened faster than I would have liked and by the end, I was dealing with a pudding like consistency of soap, and I did not get quite the shade of yellow that I would have liked. Overall, I am pretty happy with it still, and I hope that the person receiving it will like it as well.

Thursday, May 30, 2013

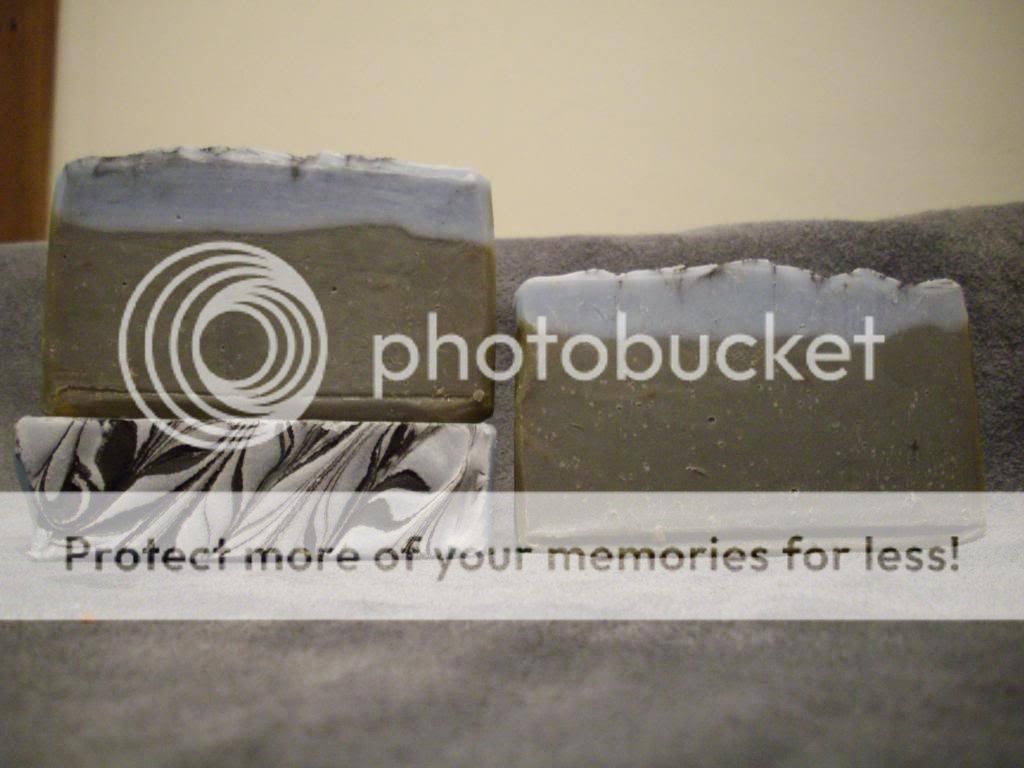

My Latest Projects

Well, I have been lousy at keeping up with pictures and my blog, but I have actually made a couple soaps in the past week or so. The first one I made was a request for another Green Tea Lemongrass soap similar to the one I did early on. It is made with a green tea infusion and dried green tea leaves in the soap along with lemongrass essential oil as a scent.

I was prepared for the fact that the soap would not be pretty as it was setting up this time, so was not terrified by the ugly brown color this time. I did run into a bit of a problem, however. I did not do very good with the liner and it folded back into the soap, so it ended up with a nasty chunk out of the top on one side. Hopefully, the friend that I made the soap for does not mind if some of the soap is not the prettiest.

This is a picture of one of the soaps that had the liner fold back unto the soap. As I said, not very pretty.

The other soap that I made just a couple days ago was using Northern Pines fragrance (which the friend that I bought it for says, "It smells kind of like Lysol, but I like that."). I made him some melt and pour soaps with the fragrance before, but wanted to make him some handmade soaps as well, so I did an in the pot swirl. It came together very easily and I think it came out fairly well except for a little ash on the top.

Hopefully, I will have more soaps forthcoming and it won't be too long between posts!

I was prepared for the fact that the soap would not be pretty as it was setting up this time, so was not terrified by the ugly brown color this time. I did run into a bit of a problem, however. I did not do very good with the liner and it folded back into the soap, so it ended up with a nasty chunk out of the top on one side. Hopefully, the friend that I made the soap for does not mind if some of the soap is not the prettiest.

This is a picture of one of the soaps that had the liner fold back unto the soap. As I said, not very pretty.

The other soap that I made just a couple days ago was using Northern Pines fragrance (which the friend that I bought it for says, "It smells kind of like Lysol, but I like that."). I made him some melt and pour soaps with the fragrance before, but wanted to make him some handmade soaps as well, so I did an in the pot swirl. It came together very easily and I think it came out fairly well except for a little ash on the top.

Hopefully, I will have more soaps forthcoming and it won't be too long between posts!

Monday, May 20, 2013

Bramble Berry Soap Swap Haul!

Well, after several days of not writing, I have two posts in one day. My package from the Bramble Berry Soap Swap arrived today! I sent in twelve soaps and received thirteen in return. It appears that I got my soap in early enough to get one of the bonus soaps made by Anne Marie from her book. I am happy with my little haul and there is a nice variety of soaps for me to try.

I am particularly fond of the scent of the Arabian Spice scent. There are also some really nice essential oil blends as well. The one made by "Dana" has a link on the back to the video showing how it was made. I haven't watched it yet as I was busy picking up the car and getting groceries today, but I plan on watching it tomorrow most likely.

My only mild disappointment with the swap was that I got two soaps with the same scent and it is not a scent I am particularly fond of (Cherry Blossom). Overall, I am very happy with the haul and I had fun opening all my little soapy gifts! I hope that the people who got the soaps that I made are not disappointed with them. I feel like such an amateur compared to some of the other soaps that I received. It was nice to see the other wrapping ideas that people had as well. Overall, I had a great time and learned from things, I think.

I am particularly fond of the scent of the Arabian Spice scent. There are also some really nice essential oil blends as well. The one made by "Dana" has a link on the back to the video showing how it was made. I haven't watched it yet as I was busy picking up the car and getting groceries today, but I plan on watching it tomorrow most likely.

My only mild disappointment with the swap was that I got two soaps with the same scent and it is not a scent I am particularly fond of (Cherry Blossom). Overall, I am very happy with the haul and I had fun opening all my little soapy gifts! I hope that the people who got the soaps that I made are not disappointed with them. I feel like such an amateur compared to some of the other soaps that I received. It was nice to see the other wrapping ideas that people had as well. Overall, I had a great time and learned from things, I think.

Long Time No Soap...

It has been a while since I have posted and my life has been a bit crazy. I have made one soap since I last posted and I plan to make some soap today if things work out as planned and the garage does not call and say the car is done before I am done with making this post. The car needed an oil change and to have the AC looked at. Hopefully, the AC is not going to be expensive as I am low on funds (as usual).

Anyways, my latest soap creation was actually made last Tuesday (I think), and I am only now getting around to posting about it now. This soap was made with my usual recipe and I used red oxide to make an in the pot swirl. I made the soap at a lower temperature as I have been doing lately, and it came together a little slowly at first, but when I started working with the color it started thickening up fairly quickly.

I managed to get it to behave long enough to get it poured into the mold and allowed the soap to gel as it did not have any milk products in it or anything that would cause it to overheat. The soap set up well and I cut it the next day as usual. Instead of taking pictures right off as I often do, I waited a bit as I had been pretty busy. When I did take the picture the creamy color of the soap had darkened, so I found out that the fragrance oil that I had used (Ginger Spice) had vanilla in it.

Overall, I am not upset with the way the soap turned out. I love the scent of ginger and while the soap is a bit darker then I had "planned" I am not upset with it as I knew very little about the fragrance oil I was using (I bought this fragrance oil through Etsy). I hope that the other scents that I picked up with this one work out well.

I will do my best to keep up better with posts here and get back in the swing of making more soaps again. I have not been feeling very inspired by much lately, which is likely part of the toll of depression. The only thing I can do is to fight against it by making more soap and working on staying active.

Anyways, my latest soap creation was actually made last Tuesday (I think), and I am only now getting around to posting about it now. This soap was made with my usual recipe and I used red oxide to make an in the pot swirl. I made the soap at a lower temperature as I have been doing lately, and it came together a little slowly at first, but when I started working with the color it started thickening up fairly quickly.

I managed to get it to behave long enough to get it poured into the mold and allowed the soap to gel as it did not have any milk products in it or anything that would cause it to overheat. The soap set up well and I cut it the next day as usual. Instead of taking pictures right off as I often do, I waited a bit as I had been pretty busy. When I did take the picture the creamy color of the soap had darkened, so I found out that the fragrance oil that I had used (Ginger Spice) had vanilla in it.

Overall, I am not upset with the way the soap turned out. I love the scent of ginger and while the soap is a bit darker then I had "planned" I am not upset with it as I knew very little about the fragrance oil I was using (I bought this fragrance oil through Etsy). I hope that the other scents that I picked up with this one work out well.

I will do my best to keep up better with posts here and get back in the swing of making more soaps again. I have not been feeling very inspired by much lately, which is likely part of the toll of depression. The only thing I can do is to fight against it by making more soap and working on staying active.

Saturday, May 11, 2013

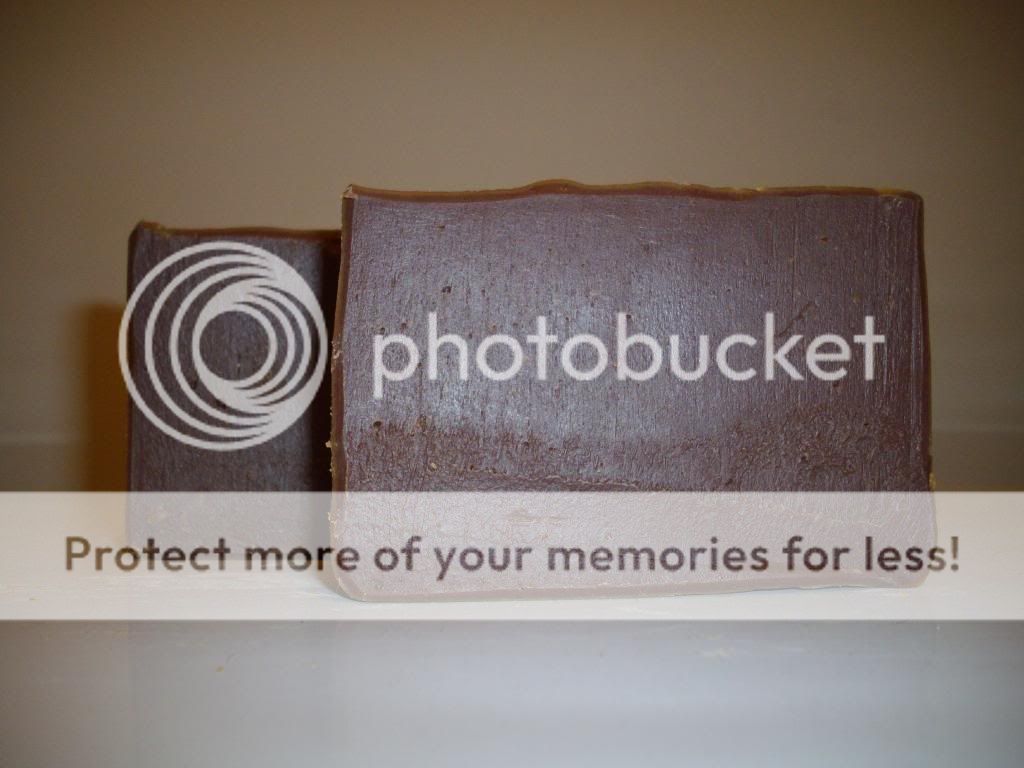

Chocolate Milk

Knowing that it was going to be a busy weekend, I made a soap sort of late on Thursday evening. I did another goat's milk soap, but this time I used chocolate fragrance oil and colored it with cocoa powder. I do not usually like foodie soaps for myself much, but I really wanted to try the cocoa soap for some reason. Maybe it is because I love chocolate so much.

Anyways, I had the goat's milk measured and frozen beforehand as I had with the oatmeal, milk and honey, but this time I measured the oils out and let them come to a reasonable temperature (about 85°) before I even took the milk out of the freezer. Again, the mix came to trace nice and slow so it I chose to do something more complicated, I would have had plenty of time to work with it. As it was, I did a plain chocolate color bar instead of doing a swirl. I added about 3 teaspoons of cocoa powder to the mix at trace and it was still a bit light when I poured it into the mold.

Like the oatmeal, milk and honey soap, I put it in the freezer to avoid scorching. I left it in the freezer for two hours then moved it to the fridge for the night. This is where things differ from the oatmeal soap. I slept poorly on Thursday evening and got up early Friday morning (kind of like I did last night, which is why I am posting so early in the morning), and took the soap from the refrigerator to see if I could unmold it. I had been a bit impatient... and the soap was not quite ready. I let it sit on the counter instead of trying to cut it immediately, and it went through gel phase. I don't mind that it did, because it darkened the soap and didn't harm anything.

After it finished gelling, I was impatient to cut it and it was still too soft. I managed to cut two pieces and then realized it was not working well, so let it sit longer. I waited several more hours to cut it and then let it sit longer until I neatened it up and took pictures. This was part of why I did not have this post yesterday instead of today. So, this is the soap I dubbed "Chocolate Milk."

In other news, the soaps for the soap swap have begun to arrive and I got a few packages in the mail yesterday. I love seeing other people's creativity and how they have wrapped their soaps and such. I am looking forward to getting more of the packages in and getting pictures of the swap soaps! I also get a bunch more soaps to try out and see how I like!

Anyways, I had the goat's milk measured and frozen beforehand as I had with the oatmeal, milk and honey, but this time I measured the oils out and let them come to a reasonable temperature (about 85°) before I even took the milk out of the freezer. Again, the mix came to trace nice and slow so it I chose to do something more complicated, I would have had plenty of time to work with it. As it was, I did a plain chocolate color bar instead of doing a swirl. I added about 3 teaspoons of cocoa powder to the mix at trace and it was still a bit light when I poured it into the mold.

Like the oatmeal, milk and honey soap, I put it in the freezer to avoid scorching. I left it in the freezer for two hours then moved it to the fridge for the night. This is where things differ from the oatmeal soap. I slept poorly on Thursday evening and got up early Friday morning (kind of like I did last night, which is why I am posting so early in the morning), and took the soap from the refrigerator to see if I could unmold it. I had been a bit impatient... and the soap was not quite ready. I let it sit on the counter instead of trying to cut it immediately, and it went through gel phase. I don't mind that it did, because it darkened the soap and didn't harm anything.

After it finished gelling, I was impatient to cut it and it was still too soft. I managed to cut two pieces and then realized it was not working well, so let it sit longer. I waited several more hours to cut it and then let it sit longer until I neatened it up and took pictures. This was part of why I did not have this post yesterday instead of today. So, this is the soap I dubbed "Chocolate Milk."

In other news, the soaps for the soap swap have begun to arrive and I got a few packages in the mail yesterday. I love seeing other people's creativity and how they have wrapped their soaps and such. I am looking forward to getting more of the packages in and getting pictures of the swap soaps! I also get a bunch more soaps to try out and see how I like!

Thursday, May 9, 2013

Oatmeal, Milk and Honey

I mentioned a bit ago that I had someone that was offering me some goat's milk. Well, I got my goat's milks on Sunday and Tuesday after freezing some of the goat's milk, I made my first milk soap. I made oatmeal, goat's milk and honey, unscented. For the most part, I kept to my usual recipe of olive, palm, coconut and castor oils, but I used the goat's milk to replace the water in my lye mixture. I used 100% goat's milk and no water in the mix.

As I had done a fair amount of reading in advance on how people have been doing goat's milk soaps, I had a pretty good idea of what I wanted to do. I measured out and froze the goat's milk in an ice cube tray the day before so it would not get too hot when I added the lye. I mixed the oils before I started mixing the lye, and next time I do this, I will wait until the oils cool some before I start adding the lye to the milk. If the goat's milk (or any milk) gets too hot as you add the lye it will overheat and scorch, turning brown and sort of curdled. While it is still usable if you do that, it does not smell very pleasant and does not have the nice creamy appearance of a bar that has not been scorched.

Well, with me, I mixed the lye to the milk cubes and the lye mixture started to rise in temperature as I waited for the oils to cool off. I ended up putting the lye mix in the freezer to avoid scorching as I did not want to add it to the oils while they were too warm. The lye mix was very thick as I poured it into the oils (I had already added a teaspoon of honey to my oils so I wouldn't forget). The mixture came to trace fairly slowly compared to what I am used to, but it seems to have done well. I added the oatmeal at trace.

I put the soap in the freezer for about three hours after I poured it, and then switched it to the refrigerator. This was to keep the soap from overheating and also kept it from gelling. It was my first soap that did not gel. Overall, I am happy with the way it turned out.

I am not sure if I will get much in with soaping this weekend, as I have some other plans that will keep me pretty busy on at least Saturday. I am hoping I will get at least one batch in, maybe more, but we will see! Until next time, soap happy :-)

As I had done a fair amount of reading in advance on how people have been doing goat's milk soaps, I had a pretty good idea of what I wanted to do. I measured out and froze the goat's milk in an ice cube tray the day before so it would not get too hot when I added the lye. I mixed the oils before I started mixing the lye, and next time I do this, I will wait until the oils cool some before I start adding the lye to the milk. If the goat's milk (or any milk) gets too hot as you add the lye it will overheat and scorch, turning brown and sort of curdled. While it is still usable if you do that, it does not smell very pleasant and does not have the nice creamy appearance of a bar that has not been scorched.

Well, with me, I mixed the lye to the milk cubes and the lye mixture started to rise in temperature as I waited for the oils to cool off. I ended up putting the lye mix in the freezer to avoid scorching as I did not want to add it to the oils while they were too warm. The lye mix was very thick as I poured it into the oils (I had already added a teaspoon of honey to my oils so I wouldn't forget). The mixture came to trace fairly slowly compared to what I am used to, but it seems to have done well. I added the oatmeal at trace.

I put the soap in the freezer for about three hours after I poured it, and then switched it to the refrigerator. This was to keep the soap from overheating and also kept it from gelling. It was my first soap that did not gel. Overall, I am happy with the way it turned out.

I am not sure if I will get much in with soaping this weekend, as I have some other plans that will keep me pretty busy on at least Saturday. I am hoping I will get at least one batch in, maybe more, but we will see! Until next time, soap happy :-)

Tuesday, May 7, 2013

Still Making Soap

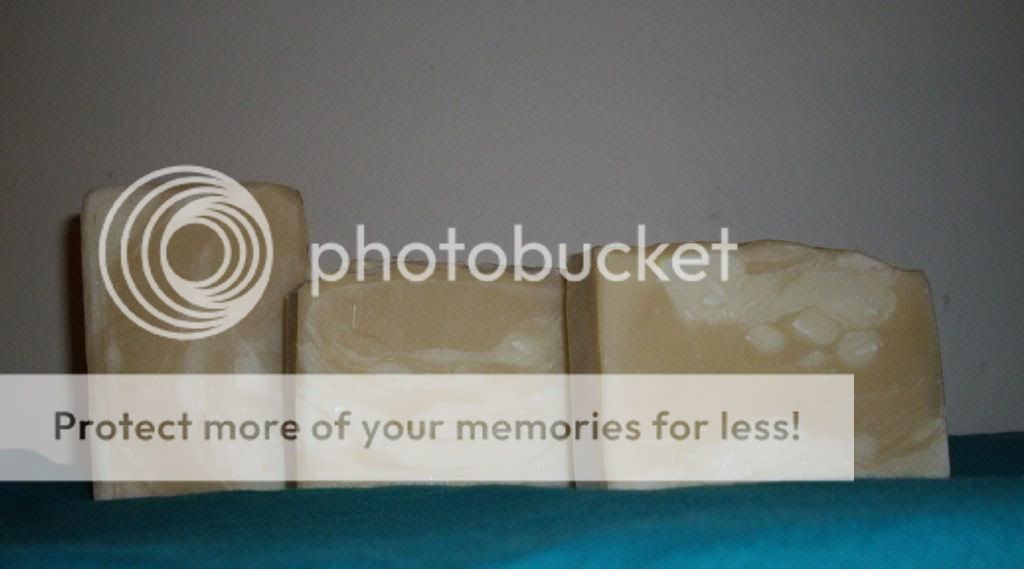

Yes, I am still making soap and still here. Things have been a bit stressed for me lately and I have been struggling with depression some, but I am still here. I made a couple soaps over the past week, but one of them I didn't post because it is my second swap soap. I think overall it came out well. The second soap that I am posting a picture of today is a plain unscented soap. I had expected it to color morph because the scent has some vanilla in it, but so far there has been no real noticeable change.

This is the first soap since I started making soaps that I did not add any color to, and I specifically didn't add it because I was not sure how dark it would get. I was a little lighter on the fragrance then I usually would be (I used a bit less then an ounce for 1.25 lbs), because I did not have enough of the fragrance left. I can still smell the fragrance now, but it is obviously lighter then my other soaps. This is a good test for me as my brother has specifically asked for lightly scented soaps. I would like to see how the scent in this holds up over time.

The soap came out fairly nice and while it looks fairly plain, I love the scent. When I make the scent again, I will know that I can play more with colors with it and will come up with something a bit more colorful or fitting for the fragrance. Oh, the fragrance is Bay Rum from Bramble Berry, and I really hope that I can place another order from Bramble Berry in the semi-near future and pick up some of their scents that I really like.

I also have handed out soaps to friends as testers and have gotten some reviews back. So far, the reviews have been almost all positive. One person has said that my soap was a little drying to her, but that her skin leans towards dry and to not be too concerned about it. The other feedback I have gotten has been good and at least one person has said that he would buy my soap. Another is looking forward to me opening my Etsy shop. At this point, I am still planning on opening in November. I will manage to get things together for setting up one way or another.

This is the first soap since I started making soaps that I did not add any color to, and I specifically didn't add it because I was not sure how dark it would get. I was a little lighter on the fragrance then I usually would be (I used a bit less then an ounce for 1.25 lbs), because I did not have enough of the fragrance left. I can still smell the fragrance now, but it is obviously lighter then my other soaps. This is a good test for me as my brother has specifically asked for lightly scented soaps. I would like to see how the scent in this holds up over time.

The soap came out fairly nice and while it looks fairly plain, I love the scent. When I make the scent again, I will know that I can play more with colors with it and will come up with something a bit more colorful or fitting for the fragrance. Oh, the fragrance is Bay Rum from Bramble Berry, and I really hope that I can place another order from Bramble Berry in the semi-near future and pick up some of their scents that I really like.

I also have handed out soaps to friends as testers and have gotten some reviews back. So far, the reviews have been almost all positive. One person has said that my soap was a little drying to her, but that her skin leans towards dry and to not be too concerned about it. The other feedback I have gotten has been good and at least one person has said that he would buy my soap. Another is looking forward to me opening my Etsy shop. At this point, I am still planning on opening in November. I will manage to get things together for setting up one way or another.

Wednesday, May 1, 2013

Another Request

I had another request yesterday for a lilac soap with purple and white tiger stripes. Before I say much more about how the soap went, let me say some things about the significance of this soap and making it yesterday. My mother died 17 years ago yesterday and lilac was her favorite scent. My sister suggested the tiger stripes and was the one that gave me this request. So, this soap is dedicated to my mother. It is also a gift to my sister as well as her birthday happens to be today (although it is going to take some time for the soap to cure, I hope she will appreciate the sentiment). The tiger stripe colors were to be done in purple and white for the two colors of lilacs.

All that said, the soap did not come together as nicely as some of my previous soaps and I had some crackle with the titanium dioxide, so my white is not as nice and smooth as it could be. I soaped at the lower temperature as I had been doing the past few times, but I still came to trace faster then I expected and by the time I started pouring the two colors... well, it wasn't so much pouring the colors as I was scooping them into the mold.

I think it smells wonderful and for all the difficulty I had with getting it together, I actually am pretty pleased with the way it turned out. The stripes are not as symmetrical or even as some of my other attempts at this swirl, and I think it looks more like a zebra stripe this time around. I hope that I can get some more lilac fragrance oil in the future and try this again, but for now this is how this one turned out.

Today I worked on my second swap soap, but what I did for it is a secret. Hopefully, it turned out well. Like my first soap for the swap, I will take pictures and save them until after the swap.

All that said, the soap did not come together as nicely as some of my previous soaps and I had some crackle with the titanium dioxide, so my white is not as nice and smooth as it could be. I soaped at the lower temperature as I had been doing the past few times, but I still came to trace faster then I expected and by the time I started pouring the two colors... well, it wasn't so much pouring the colors as I was scooping them into the mold.

I think it smells wonderful and for all the difficulty I had with getting it together, I actually am pretty pleased with the way it turned out. The stripes are not as symmetrical or even as some of my other attempts at this swirl, and I think it looks more like a zebra stripe this time around. I hope that I can get some more lilac fragrance oil in the future and try this again, but for now this is how this one turned out.

Today I worked on my second swap soap, but what I did for it is a secret. Hopefully, it turned out well. Like my first soap for the swap, I will take pictures and save them until after the swap.

Tuesday, April 30, 2013

An Experiment by Request

Well, I put out there is anyone wanted me to try any techniques or anything, and I got a reply on Facebook that someone wanted me to try changing my recipe some and do an experiment with a few different things. The challenge was to make a soap that was primarily olive oil with 20% or less of palm and coconut oil. She also wanted me to add some salt and sugar to the recipe to see how it changed things. It will likely be hard for me to gauge all the changes because they all happened at once, so I can't say for certain which did what.

Anyways, the recipe I chose to use was 60% olive oil, 20% coconut oil, 15% palm oil, and 5% Shea butter. I also added a teaspoon each of sea salt and sugar (as usual, I was making a fairly small batch 1.25 pounds of oils, so I used a little less then a teaspoon of salt and sugar per pound of oils in the recipe). Things went together smoothly and I mixed the lye with the oils at about 110° F. Things reached trace fairly slowly even using a flowery fragrance, and remained relatively thin while I separated my batter for coloring.

I chose to do an in the pot swirl as I was not sure how things would come together with the new recipe. I would have had plenty of time if I wanted to do something more complex though. I used green oxide and titanium dioxide for the colorants. I was able to unmold the soap after 14 hours, but it was still very soft. I usually cut right after I unmold and had to wait another three hours before I could cut it and it was still pretty soft then. I believe this will need a slightly longer curing time then I usually have, but it is not like I am lacking in soap to use right now.

The results of the experiment were a soft and very smooth feeling soap. I am not sure about the lather of it at this point or how long it will take to cure. It feels damp to me at this point. I am otherwise happy with the experiment and time will tell on the rest.

In other news, I dropped off a batch of soap with some testers last night. I think overall they went fairly well, but I am not as sure what this group of people like for scents. I also plan to bring the soaps to my gaming group this weekend and seeing if some of my friends there are interested in some as well. I was also offered some goat's milk to make soap with as well, so I will have some more new testing to do in the near future. I hope to hear back from my friends about the soaps they have tried and have some more feedback on ways to modify my recipe(s) to make soap that works well and is still moisturizing and such. I am not sure I am the greatest to tell if a soap is too drying as a lot of times my skin tends to be a bit more oily, so getting others impressions will be good for me!

Anyways, the recipe I chose to use was 60% olive oil, 20% coconut oil, 15% palm oil, and 5% Shea butter. I also added a teaspoon each of sea salt and sugar (as usual, I was making a fairly small batch 1.25 pounds of oils, so I used a little less then a teaspoon of salt and sugar per pound of oils in the recipe). Things went together smoothly and I mixed the lye with the oils at about 110° F. Things reached trace fairly slowly even using a flowery fragrance, and remained relatively thin while I separated my batter for coloring.

I chose to do an in the pot swirl as I was not sure how things would come together with the new recipe. I would have had plenty of time if I wanted to do something more complex though. I used green oxide and titanium dioxide for the colorants. I was able to unmold the soap after 14 hours, but it was still very soft. I usually cut right after I unmold and had to wait another three hours before I could cut it and it was still pretty soft then. I believe this will need a slightly longer curing time then I usually have, but it is not like I am lacking in soap to use right now.

The results of the experiment were a soft and very smooth feeling soap. I am not sure about the lather of it at this point or how long it will take to cure. It feels damp to me at this point. I am otherwise happy with the experiment and time will tell on the rest.

In other news, I dropped off a batch of soap with some testers last night. I think overall they went fairly well, but I am not as sure what this group of people like for scents. I also plan to bring the soaps to my gaming group this weekend and seeing if some of my friends there are interested in some as well. I was also offered some goat's milk to make soap with as well, so I will have some more new testing to do in the near future. I hope to hear back from my friends about the soaps they have tried and have some more feedback on ways to modify my recipe(s) to make soap that works well and is still moisturizing and such. I am not sure I am the greatest to tell if a soap is too drying as a lot of times my skin tends to be a bit more oily, so getting others impressions will be good for me!

Sunday, April 28, 2013

Mountain Lake Soapy Goodness

Well, after taking a night off from making soap, I came back and had another success. I ran out of castor oil again, so I made another soap with just olive, coconut and palm oils. I also think I know part of what my problem is with my soap coming to trace so fast and moving so fast, in general. I believe that I have been mixing my oil and lye a bit warmer than I should and that it has been causing the acceleration. Last night I specifically mixed cooler and had more time to work on my tiger stripe pattern without rushing through it.

With one issue down, I also wisely had lined my mold the day before so it would be ready for last night. I was really ready for a change! I mixed my oils and had my colorants ready, then came and looked through some posts on the Soap Making Forum while I was letting things cool off. I think my only real complaint about how things came together in the actual soap making process was that I was very messy in pouring my soap and got it everywhere. I managed to get most things cleaned up, but my shiny new mold had not been looking shiny and new anymore!

Anyways, for my soap, I used Mountain Lake fragrance oil from Peak Candle Supply. For colorants, I used titanium dioxide and cobalt ultramarine. I did the tiger or zebra stripe pattern again, and I think it was my best attempt at it, even as messy as things were. I will let you decide though!

I believe the next soap I will have time for will be on Tuesday and it will likely be one of the soaps I send for the swap. I am likely not going to post pictures of it, but I may find some other things to post pictures of or post about in the meantime. I know I don't have a huge following or anything, but I was wondering it there are any soaps that anyone who reads this would like me to try or has suggestions for. I am somewhat limited by finances on some things, but I have most color choices at this point. As for fragrances, I have some and will see what i can do if there are any special requests!

With one issue down, I also wisely had lined my mold the day before so it would be ready for last night. I was really ready for a change! I mixed my oils and had my colorants ready, then came and looked through some posts on the Soap Making Forum while I was letting things cool off. I think my only real complaint about how things came together in the actual soap making process was that I was very messy in pouring my soap and got it everywhere. I managed to get most things cleaned up, but my shiny new mold had not been looking shiny and new anymore!

Anyways, for my soap, I used Mountain Lake fragrance oil from Peak Candle Supply. For colorants, I used titanium dioxide and cobalt ultramarine. I did the tiger or zebra stripe pattern again, and I think it was my best attempt at it, even as messy as things were. I will let you decide though!

I believe the next soap I will have time for will be on Tuesday and it will likely be one of the soaps I send for the swap. I am likely not going to post pictures of it, but I may find some other things to post pictures of or post about in the meantime. I know I don't have a huge following or anything, but I was wondering it there are any soaps that anyone who reads this would like me to try or has suggestions for. I am somewhat limited by finances on some things, but I have most color choices at this point. As for fragrances, I have some and will see what i can do if there are any special requests!

Friday, April 26, 2013

Excitement to Disappointment

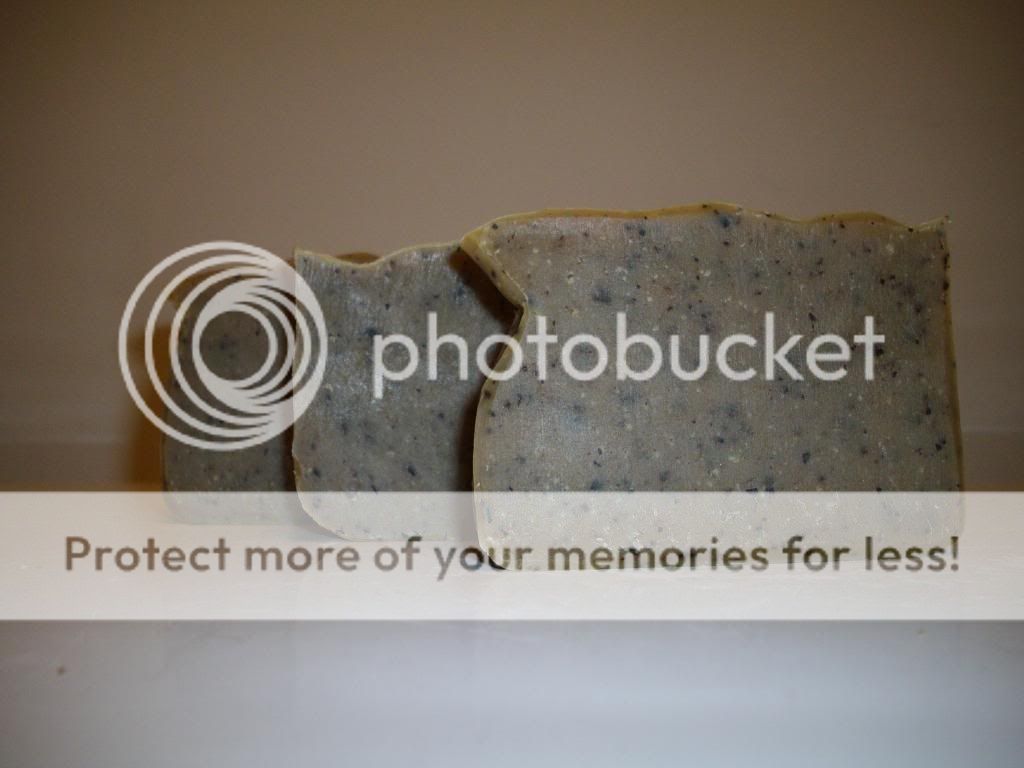

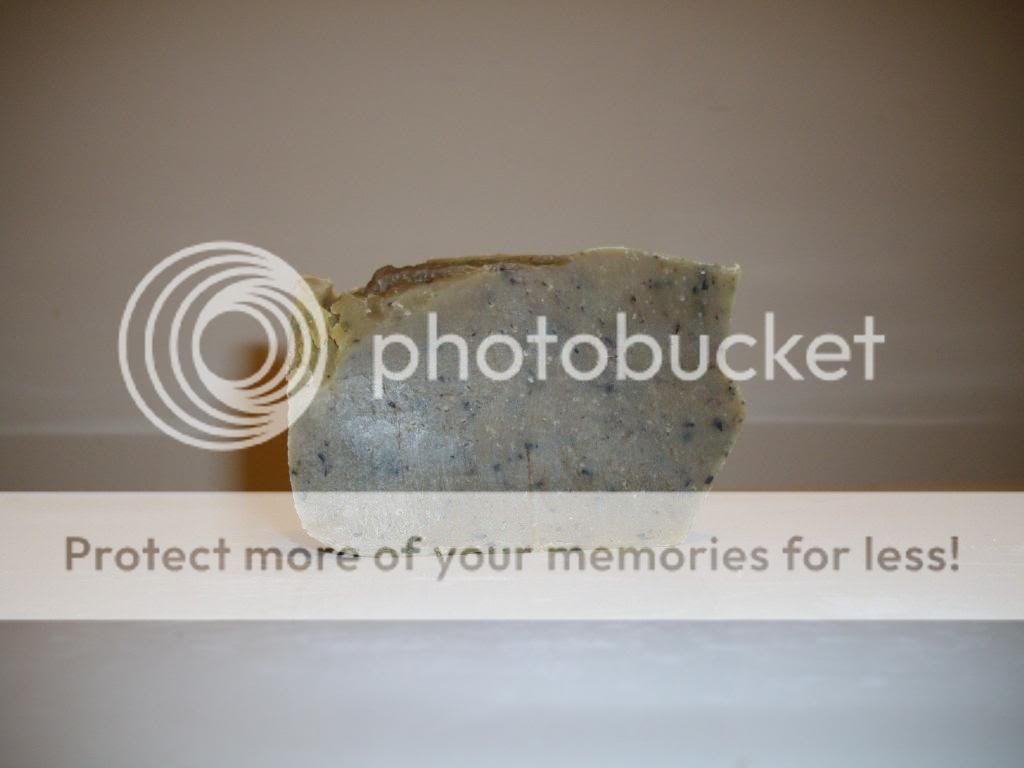

Well, I had an interesting soaping experience last night. I had a soap that did not speed up on me and was actually slow coming to trace. It was kind of weird having time to work with it. I was really in a groove and added the fragrance oil to the portion of the batter I wanted it in and it did not accelerate on me. I then added some black mica and it turned grey, so I added some activated charcoal as well. I had plenty of time to do all that and things were going great. I turned around to pour my soap in the mold to find out I had forgotten to line it.

I was able to remedy that situation quick enough, and got the mold lined. My soap was thickening as I poured it, but it was no worse then some of my others had been. I figured I would practice another mica swirl on the top and I was very happy with the way it worked. All things considered, everything came together really well and I was really looking forward to checking out my soap this morning.

The disappointment came when it was time to take it out of the mold and it was still a little warm and soft. I could not resist taking a peak to see how it looked and was disappointed to see that the black I had worked so hard to get had morphed into a drab olive green on the outside. This was not a feature to me. The inside of the soap seems to be a light gray at this point while the outside has remained olive green. Time will tell if it will stay that way.

Overall, I would say that it was still a successful soaping experience. I would like to know why this soap behaved so differently then my other soaps have. I used my usual recipe and soaped at the same temperature I usually do. I guess I may figure it out eventually, but for now it is a mystery to me. I may or may not be making another soap tonight. If not, I will definitely make one tomorrow.

I was able to remedy that situation quick enough, and got the mold lined. My soap was thickening as I poured it, but it was no worse then some of my others had been. I figured I would practice another mica swirl on the top and I was very happy with the way it worked. All things considered, everything came together really well and I was really looking forward to checking out my soap this morning.

The disappointment came when it was time to take it out of the mold and it was still a little warm and soft. I could not resist taking a peak to see how it looked and was disappointed to see that the black I had worked so hard to get had morphed into a drab olive green on the outside. This was not a feature to me. The inside of the soap seems to be a light gray at this point while the outside has remained olive green. Time will tell if it will stay that way.

Overall, I would say that it was still a successful soaping experience. I would like to know why this soap behaved so differently then my other soaps have. I used my usual recipe and soaped at the same temperature I usually do. I guess I may figure it out eventually, but for now it is a mystery to me. I may or may not be making another soap tonight. If not, I will definitely make one tomorrow.

Thursday, April 25, 2013

My Ugly Soap

Well, my first soap ever was a disaster (well, it was lye heavy and makes a nice laundry soap, so not a total failure), but since then I have been mostly happy with most of the soaps I have done. That is until the one I did last night. It isn't terrible, but it is not what I wanted either. I was trying to get something that had a sort of camo appearance to it, but with different colors then camouflage usually has. I wanted a red, brown and green. The problems I had were that my soap thickened up too much too fast yet again and that the red and brown were too close together in shade, but I wasn't sure how to change it much with the thickness of the batter already.

So, I guess my soap isn't too bad, but to me it is fairly ugly as it is nothing like I envisioned it to be. It is fairly blocky instead of being as random as I would have wanted it to be. There is one thing I can say that I love about it though, and that is the scent. I used Peak's Cinnamon and Balsam and I am in love with it. I love spicy scents and the hints of a woodsy fragrance in the background just make it more appealing to me. So, anyways, here is my ugly soap!

In other soaping news, I made my soap for the swap and I am happy with the way it turned out, but I am not going to post pictures until after the swap. I hope that it holds up well through curing and shipping and all. I have plans for a second item that I will be making for the swap as well, but I need to wait until some supplies arrive from Wholesale Supplies Plus. I have one order that I placed with them that should be shipping soon, and another one that is due today. I need to wait for the one that has yet to ship sadly.

Today's shipment should hold a couple new fragrances, some more titanium dioxide, yellow oxide and ultramarine blue. I have a plan already for making a soap with the blue today or tonight. The way it is looking it will be tonight, as I also have to visit my partner in the hospital today and my order just arrived now. (I was just about to say it hadn't arrived yet and the UPS delivery guy showed up at the door) I should be back tomorrow to show you something with blue. It would be nice to have something with a new color!

So, I guess my soap isn't too bad, but to me it is fairly ugly as it is nothing like I envisioned it to be. It is fairly blocky instead of being as random as I would have wanted it to be. There is one thing I can say that I love about it though, and that is the scent. I used Peak's Cinnamon and Balsam and I am in love with it. I love spicy scents and the hints of a woodsy fragrance in the background just make it more appealing to me. So, anyways, here is my ugly soap!

In other soaping news, I made my soap for the swap and I am happy with the way it turned out, but I am not going to post pictures until after the swap. I hope that it holds up well through curing and shipping and all. I have plans for a second item that I will be making for the swap as well, but I need to wait until some supplies arrive from Wholesale Supplies Plus. I have one order that I placed with them that should be shipping soon, and another one that is due today. I need to wait for the one that has yet to ship sadly.

Today's shipment should hold a couple new fragrances, some more titanium dioxide, yellow oxide and ultramarine blue. I have a plan already for making a soap with the blue today or tonight. The way it is looking it will be tonight, as I also have to visit my partner in the hospital today and my order just arrived now. (I was just about to say it hadn't arrived yet and the UPS delivery guy showed up at the door) I should be back tomorrow to show you something with blue. It would be nice to have something with a new color!

Tuesday, April 23, 2013

Sorry!

Sorry I did not post a cut picture like I said I was going to yesterday. The day was pretty busy for me and I just ran out of time with all the errands I had to run. I also was not able to make my soap for the soap swap yesterday either. I ran out of parchment paper so had to run to the store and pick up some freezer paper to line my mold with. By the time I got back home, it was time for me to run out to the hospital and visit my partner. I seemed to always not have enough time to post or make soap!

So, I think the mica swirl for the challenge came out very well, even if it was late to actually turn in for the challenge. So you know, I used Nag Champa to scent the bottom portion of the soap and left the top part with the red mica swirl unscented. The brown portion is colored with brown oxide. So without further ado, the mica swirl!

One of the other things that I did yesterday while I was running around madly, was mail out some soaps to my friend Matt in Washington and mail out some stuff including soap to another friend. I was up until about 4:00 am the night before designing and cutting out the labels. I think I can make the labels faster now that I know what I am doing. Cutting them out on the other hand and looking good when they are done may take more talent then I have. I have mentioned not being able to cut a straight line before... well, my ability to cut a circle is worse!

Anyways, these are some of my round soaps all wrapped up pretty (or as pretty as I could get them), and ready to be shipped out. They are due to arrive with my friends on Wednesday and I am hoping that they get favorable reviews.

So, I think the mica swirl for the challenge came out very well, even if it was late to actually turn in for the challenge. So you know, I used Nag Champa to scent the bottom portion of the soap and left the top part with the red mica swirl unscented. The brown portion is colored with brown oxide. So without further ado, the mica swirl!

One of the other things that I did yesterday while I was running around madly, was mail out some soaps to my friend Matt in Washington and mail out some stuff including soap to another friend. I was up until about 4:00 am the night before designing and cutting out the labels. I think I can make the labels faster now that I know what I am doing. Cutting them out on the other hand and looking good when they are done may take more talent then I have. I have mentioned not being able to cut a straight line before... well, my ability to cut a circle is worse!

Anyways, these are some of my round soaps all wrapped up pretty (or as pretty as I could get them), and ready to be shipped out. They are due to arrive with my friends on Wednesday and I am hoping that they get favorable reviews.

Sunday, April 21, 2013

Lots of Soap Pictures!

As promised, I have a picture of the soap that I cut yesterday but did not have a picture of. This was the Juniper Breeze soap with an in the pot swirl done in green oxide. This was the soap that I poured Friday night and managed to make such a mess with. All things considered, I think it looks fairly nice if I do say so myself.

This second soap is one I did late last night after visiting my partner in the hospital. I attempted to do another tiger swirl and it was not quite as successful as my first one (at least to me). As with many of my soaping attempts, it thickened up faster then I would have liked and by the time I got to the top I was sort of slopping it into the mold. I also noticed that the black in this started to show natural color around the edges and seemed to have some crackle effect to it. I am not sure if it overheated or what happened. I might have to post on the forum and ask about it. I seem to be getting that more since I have been putting the mold inside the box to preserve the tops of the soap. It may be an effect of that or something else entirely. This is scented with Blackberry Sage and colored with green oxide and black mica.

This third picture I debated not posting as this soap is sort of a trial for my soap for the swap I am hosting. I would kind of like to keep what I am doing a surprise, but I know myself well enough to know that I won't be very good at it! This soap is also my (late again) challenge from the Great Cakes Soapworks week three challenge. The challenge was to do a mica swirl on the top of a soap, so this is my first attempt at a mica swirl. The soap is still in the mold and wet, and will likely look rather different after it has gelled, but I wanted to give you a preview picture.

This second soap is one I did late last night after visiting my partner in the hospital. I attempted to do another tiger swirl and it was not quite as successful as my first one (at least to me). As with many of my soaping attempts, it thickened up faster then I would have liked and by the time I got to the top I was sort of slopping it into the mold. I also noticed that the black in this started to show natural color around the edges and seemed to have some crackle effect to it. I am not sure if it overheated or what happened. I might have to post on the forum and ask about it. I seem to be getting that more since I have been putting the mold inside the box to preserve the tops of the soap. It may be an effect of that or something else entirely. This is scented with Blackberry Sage and colored with green oxide and black mica.

This third picture I debated not posting as this soap is sort of a trial for my soap for the swap I am hosting. I would kind of like to keep what I am doing a surprise, but I know myself well enough to know that I won't be very good at it! This soap is also my (late again) challenge from the Great Cakes Soapworks week three challenge. The challenge was to do a mica swirl on the top of a soap, so this is my first attempt at a mica swirl. The soap is still in the mold and wet, and will likely look rather different after it has gelled, but I wanted to give you a preview picture.

Saturday, April 20, 2013

Two Soap Night

So, last night I had to take my partner to the hospital for problems with depression. This left me feeling pretty stressed out myself, so I dealt with that stress by making soap of course. I had run out of castor oil, so had to modify my normal recipe. I had decided I wanted a purple color, so I used alkanet root powder. I had not finished my infusion, so I added half a teaspoon at trace.

I was pleasantly surprised by how smoothly everything worked out. I used the fragrance oil Country Garden from Peaks Candle Supply. The powder mixed in easily enough despite me spilling a fair amount on my stick blender. The resulting soap turned a nice dark purple, but that shade may change as the soap cures.

The second soap I made last night was scented with Juniper Breeze. I used green oxide and did an in the pot swirl. This soap I poured into my PVC mold as my log mold was already being used. I had done some rearranging in the kitchen and the place I normally used for keeping my mold steady had been removed. I found a place to put the mold after it was filled, but did not know how to brace it to pour.

I then got the (not so) brilliant idea to hold it against the sink and brace it with my stomach. I soon realized that holding the mold upright, pouring soap, and holding the bowl of soap batter is easier said than done. I managed to get most of the soap into the mold without making too much of a mess. I will likely post pictures of that one tomorrow. I have taken it out of its mold, but still need to take pictures of it.

In other news, I got an order of essential oils in this afternoon. It was only two essential oils (lavender and lemongrass), but they were both eight ounce bottles. I also was able to put in an order with Wholesale Supplies Plus last night thanks to my friend Matt (aka Jethal from EverQuest 2). So a big thank you to Matt! I would also like to thank Elizabeth from the Soap Making Forum for all the help she has given me with the soap swap that I am hosting. She has been great at keeping me on track and remembering the little things that I might otherwise forget.

In other news, I got an order of essential oils in this afternoon. It was only two essential oils (lavender and lemongrass), but they were both eight ounce bottles. I also was able to put in an order with Wholesale Supplies Plus last night thanks to my friend Matt (aka Jethal from EverQuest 2). So a big thank you to Matt! I would also like to thank Elizabeth from the Soap Making Forum for all the help she has given me with the soap swap that I am hosting. She has been great at keeping me on track and remembering the little things that I might otherwise forget.

Thursday, April 18, 2013

Busy Few Days

So, it has been a few days since I have written. I meant to write yesterday, but I ended up being pretty busy and things were kind of insane for me. I don't always multitask well, so I ended up not getting some things I wanted to done. I made a soap Tuesday, and cut it yesterday morning. I wanted to take pictures and post them, but it was not to be. I did manage to get the pictures today and will post one here with this.

As for what has me so busy, I have started to organize an unofficial soap swap with a bunch of people from the Soap Making Forum. As I have not been a member long enough, I can't be in a swap, much less host one. It was suggested that I could host one through facebook unofficially, so I started getting things together and have been busy organizing people. I really have to thank the others on the list that are helping me with organizing. I am so happy with the group of people that we have involved in the swap. I am really looking forward to see the creations that everyone comes up with!

Okay, I will try to stop bouncing around about the soap swap for a little bit at least and talk about the soap I made on Tuesday. I made an in the pot swirl using three colors to try and make the look of a cloudy night. Not sure I succeeded, but that was the plan. I used the scent Midsummer Night, which is likely my favorite Yankee Candle scent. I was doing good with the soap until I added the fragrance oil (at partial emulsification, I forgot to add it before I started mixing again), once the fragrance oil began to mix in it immediately started to accelerate.

Even with the fast trace, I was still able to get the soap together without too much difficulty. It was pretty thick when I poured it into the mold and was hard to get a nice look on the top, but it turned out fairly well. I also tried a new method of insulating it and put the mold inside a refrigerator soda pack box and then insulating the box so I didn't damage the top of the soap with plastic wrap. The things I noticed with this is that the top cracked a little bit and the white at the top turned sort of pinkish. I am not sure if that was a sign of overheating or if it was some discoloration from the fragrance oil.

As for what has me so busy, I have started to organize an unofficial soap swap with a bunch of people from the Soap Making Forum. As I have not been a member long enough, I can't be in a swap, much less host one. It was suggested that I could host one through facebook unofficially, so I started getting things together and have been busy organizing people. I really have to thank the others on the list that are helping me with organizing. I am so happy with the group of people that we have involved in the swap. I am really looking forward to see the creations that everyone comes up with!

Okay, I will try to stop bouncing around about the soap swap for a little bit at least and talk about the soap I made on Tuesday. I made an in the pot swirl using three colors to try and make the look of a cloudy night. Not sure I succeeded, but that was the plan. I used the scent Midsummer Night, which is likely my favorite Yankee Candle scent. I was doing good with the soap until I added the fragrance oil (at partial emulsification, I forgot to add it before I started mixing again), once the fragrance oil began to mix in it immediately started to accelerate.

Even with the fast trace, I was still able to get the soap together without too much difficulty. It was pretty thick when I poured it into the mold and was hard to get a nice look on the top, but it turned out fairly well. I also tried a new method of insulating it and put the mold inside a refrigerator soda pack box and then insulating the box so I didn't damage the top of the soap with plastic wrap. The things I noticed with this is that the top cracked a little bit and the white at the top turned sort of pinkish. I am not sure if that was a sign of overheating or if it was some discoloration from the fragrance oil.

Monday, April 15, 2013

Another Adventure

After a few days without soaping and feeling the desire to make soap grow on me, I finally broke down yesterday afternoon and made some soap using my rubber gloves that are a bit to small for me. Things actually were going really well for me and I thought I was going to make it through my soaping for the day without an adventure in the process, but it didn't quite happen that way.

Before I start this, let me tell you a couple things. I spend Sunday through Wednesday evenings in an online game which involves getting together with another 23 like-minded people and fighting big nasty monsters on a computer screen. This keeps me entertained and distracted those evenings. Days when I don't do that and don't have other things to do, I consider my busy soaping days. When I ran out of gloves on Thursday, this left me the rest of the weekend with no soap to make. Let's just say that I was feeling a little grumpy about going those days without being able to make any soap.

So, I finally decide that I am going to make my soap and I have plans that evening, so I can't take too long in making it. I was not planning on anything too complicated, so this seemed like it was a great plan. My partner was in bed, so I took my iPod and even was able to listen to some music as I made my soap. Now, I have my nice new mold that needs to be lined before I can pour the soap into it, but I usually have plenty of time between when I pour my lye and when I actually start mixing the soap. I basically said to myself that I could line the mold after I had the lye and oils measured, but before I mixed it. There was time in between to wait as the lye had to cool.

Well, as you may have guessed, I measured everything out, then got my fragrance oil ready, and made sure my colorant was ready. Now at this time, I started asking myself what it was that I had forgotten, but I rechecked to make sure I had measured out all the oils and lye and water correctly and had my color and fragrance ready for mixing. I even did dishes while I was waiting for things to cool, because I had plenty of time. Then I began mixing my soap, and it was not until I had the green color that I wanted and was saying to myself that it was nice to actually get to this point and not have my soap be too thick when it dawned on me that the mold was still not lined.

So, I grabbed my parchment paper and tried to rapidly get it to line the mold the way I like. Well, it is a new mold, and my gloves didn't fit right and quick was not happening. I ended up ripping off the gloves and folding the paper without the gloves on and then quickly moving back to my now thick soap. I stirred it all up again, and then did my pouring and in the pot swirl and then poured it into the mold.

Anyways, the soap is none the worse for the wear and I am actually pretty happy with the result. Oh, this is scented with Lemongrass and Sage fragrance oil from Peaks. I used Woodland Green Oxide from Wholesale Supplies Plus for the color.

Before I start this, let me tell you a couple things. I spend Sunday through Wednesday evenings in an online game which involves getting together with another 23 like-minded people and fighting big nasty monsters on a computer screen. This keeps me entertained and distracted those evenings. Days when I don't do that and don't have other things to do, I consider my busy soaping days. When I ran out of gloves on Thursday, this left me the rest of the weekend with no soap to make. Let's just say that I was feeling a little grumpy about going those days without being able to make any soap.

So, I finally decide that I am going to make my soap and I have plans that evening, so I can't take too long in making it. I was not planning on anything too complicated, so this seemed like it was a great plan. My partner was in bed, so I took my iPod and even was able to listen to some music as I made my soap. Now, I have my nice new mold that needs to be lined before I can pour the soap into it, but I usually have plenty of time between when I pour my lye and when I actually start mixing the soap. I basically said to myself that I could line the mold after I had the lye and oils measured, but before I mixed it. There was time in between to wait as the lye had to cool.

Well, as you may have guessed, I measured everything out, then got my fragrance oil ready, and made sure my colorant was ready. Now at this time, I started asking myself what it was that I had forgotten, but I rechecked to make sure I had measured out all the oils and lye and water correctly and had my color and fragrance ready for mixing. I even did dishes while I was waiting for things to cool, because I had plenty of time. Then I began mixing my soap, and it was not until I had the green color that I wanted and was saying to myself that it was nice to actually get to this point and not have my soap be too thick when it dawned on me that the mold was still not lined.

So, I grabbed my parchment paper and tried to rapidly get it to line the mold the way I like. Well, it is a new mold, and my gloves didn't fit right and quick was not happening. I ended up ripping off the gloves and folding the paper without the gloves on and then quickly moving back to my now thick soap. I stirred it all up again, and then did my pouring and in the pot swirl and then poured it into the mold.

Anyways, the soap is none the worse for the wear and I am actually pretty happy with the result. Oh, this is scented with Lemongrass and Sage fragrance oil from Peaks. I used Woodland Green Oxide from Wholesale Supplies Plus for the color.

Saturday, April 13, 2013

You May be Addicted to Soap Making...

I made my last soap on Thursday and I have not been very busy the past couple days and I have gotten a little twitchy. I really want to make a soap! If you are wondering why I am not making soap and instead just whining about not making any, it is because I ran out of latex gloves. I always use gloves when I soap because of the caustic natural of soap and I am attempting to be safe with it. I ordered new gloves and they are due in on Monday. That means another day without making a soap.

On the plus side of things, the organza bags that I ordered to wrap my soap for the Bramble Berry Soap Swap came in today. This meant I got to clean up my Cranberry Fig soap a bit and put it in the bags so it would be ready to send out to the swap on Monday. I cannot put the name that I would like to use as a business name on the tags that I made up for the soap, but I did put a badger on them. I made up the tags on a free program and cut them out by hand (yes, that means they aren't cut straight).

I am a bit nervous about the swap and hope that my soap is good enough for it. I know I shouldn't worry about it, but it is that perfectionist nature that I have. I wish it was better then it was, but it is what it is. I have the date that it finishes curing on the bars, and they are wrapped and I think they do not look terrible anyways. They even look semi-professional in my opinion. I will let you decide.

In other news, I received some other things in the mail yesterday. I got some tussah silk to try in my soaps as well as some herbs for adding as natural colorants. I have some of the herbs infusing now (alkanet root powder, spirulina powder, and madder root powder). They should be done in a few weeks. The infusions take a minimum of two weeks and I am really looking forward to working with them. I also have a little powder left over and might see about adding some of the powdered herbs at trace to see how they work out. I especially want to work some with the alkanet, as I have some fragrance oils that I would like to be purple. I will have to see what happens on Monday between doctor appointments, dropping off my package and some other errands. Hopefully, I will have time to make a soap although I am not sure what I will make yet.

On the plus side of things, the organza bags that I ordered to wrap my soap for the Bramble Berry Soap Swap came in today. This meant I got to clean up my Cranberry Fig soap a bit and put it in the bags so it would be ready to send out to the swap on Monday. I cannot put the name that I would like to use as a business name on the tags that I made up for the soap, but I did put a badger on them. I made up the tags on a free program and cut them out by hand (yes, that means they aren't cut straight).

I am a bit nervous about the swap and hope that my soap is good enough for it. I know I shouldn't worry about it, but it is that perfectionist nature that I have. I wish it was better then it was, but it is what it is. I have the date that it finishes curing on the bars, and they are wrapped and I think they do not look terrible anyways. They even look semi-professional in my opinion. I will let you decide.

In other news, I received some other things in the mail yesterday. I got some tussah silk to try in my soaps as well as some herbs for adding as natural colorants. I have some of the herbs infusing now (alkanet root powder, spirulina powder, and madder root powder). They should be done in a few weeks. The infusions take a minimum of two weeks and I am really looking forward to working with them. I also have a little powder left over and might see about adding some of the powdered herbs at trace to see how they work out. I especially want to work some with the alkanet, as I have some fragrance oils that I would like to be purple. I will have to see what happens on Monday between doctor appointments, dropping off my package and some other errands. Hopefully, I will have time to make a soap although I am not sure what I will make yet.

Friday, April 12, 2013

A Personal Challenge

There was a challenge posted on Great Cakes Soapworks blog to make an elemental swirl soap. This consisted of doing two three color in the pot swirls with different shades and a pencil line in between the two swirled areas. Many of the soaps were done with elemental themes, such as fire and water or earth and sky. I have to say that the soaps that were posted on the Soap Making Forum were amazing. I wanted to try my hand at this, but I was having a hard time of figuring out which elements to chose.

In looking through photos on the forum yesterday, it suddenly hit me. The element that struck me was to do the element of spirit. I then had to figure out which element to do with it, or what would go with the theme, and inspiration was with me still as I realized I could do a soap based on Heart and Soul. The challenge suggested that beginners do one color for each swirl plus the base color, but well, for me it was important that each swirl had three colors because of spiritual significance. I believe that spirituality is a balance between body, mind and spirit and that all must be fed for spiritual health. That is one of the threes, the other is that I am connected to a triple aspect goddess.

With this in mind, I planned my soap in its two sections. The heart would be done in two shades of red plus the soaps base color. I have a red mica and red oxide, so that worked for the two reds. (They sort of blended together and can't really be distinguished in the soap at this point, that may or may not change as it cures) I wanted the reds and base color to represent the heart both figuratively and literally. As white and red blood cells moving through blood in the body in a literal sense, and as an emotional sense of vitality. The soul or spirit section of the soap was done in black, grey and white as I wanted an ethereal feel of actual spirits. For a fragrance, I chose the scent Eternity as it seemed fitting. The pencil line was done in cinnamon mostly because it was what I had available.

As far as the process of the soap actually coming together, I did what I said I wasn't going to do and over blended it again before I started pouring and ended up with it being very thick again. This was not then end of the world, but it did make it a bit more difficult to work with. I also learned the valuable lesson of always mixing your colors after you pour them into their separate cups rather then waiting until right before you are going to use them, especially if your mixture is getting too thick already. Let's just say that I had to stick blend the reds within an inch of their lives to get the colors blended.

I think for my first time doing something this complex, that it came out rather well. I am also happy with my first pencil line. I will try to once again remember my lesson on over blending and may even see about changing my recipe a bit to see about getting something that doesn't set up as quickly as was suggested to me. So, this is the latest creation:

In looking through photos on the forum yesterday, it suddenly hit me. The element that struck me was to do the element of spirit. I then had to figure out which element to do with it, or what would go with the theme, and inspiration was with me still as I realized I could do a soap based on Heart and Soul. The challenge suggested that beginners do one color for each swirl plus the base color, but well, for me it was important that each swirl had three colors because of spiritual significance. I believe that spirituality is a balance between body, mind and spirit and that all must be fed for spiritual health. That is one of the threes, the other is that I am connected to a triple aspect goddess.

With this in mind, I planned my soap in its two sections. The heart would be done in two shades of red plus the soaps base color. I have a red mica and red oxide, so that worked for the two reds. (They sort of blended together and can't really be distinguished in the soap at this point, that may or may not change as it cures) I wanted the reds and base color to represent the heart both figuratively and literally. As white and red blood cells moving through blood in the body in a literal sense, and as an emotional sense of vitality. The soul or spirit section of the soap was done in black, grey and white as I wanted an ethereal feel of actual spirits. For a fragrance, I chose the scent Eternity as it seemed fitting. The pencil line was done in cinnamon mostly because it was what I had available.

As far as the process of the soap actually coming together, I did what I said I wasn't going to do and over blended it again before I started pouring and ended up with it being very thick again. This was not then end of the world, but it did make it a bit more difficult to work with. I also learned the valuable lesson of always mixing your colors after you pour them into their separate cups rather then waiting until right before you are going to use them, especially if your mixture is getting too thick already. Let's just say that I had to stick blend the reds within an inch of their lives to get the colors blended.

I think for my first time doing something this complex, that it came out rather well. I am also happy with my first pencil line. I will try to once again remember my lesson on over blending and may even see about changing my recipe a bit to see about getting something that doesn't set up as quickly as was suggested to me. So, this is the latest creation:

Thursday, April 11, 2013

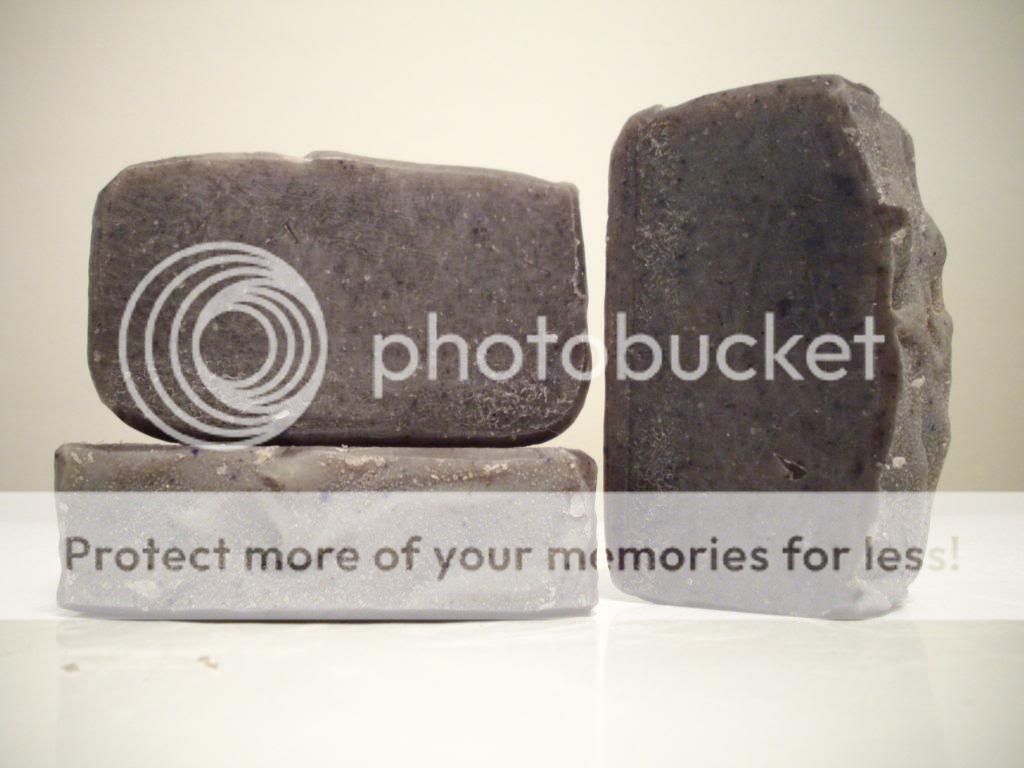

The Wonders of Vanilla

This morning I got up and did my normal check-ins on the Soap Making Forum (did I mention that I am addicted to this whole soap making thing?), and there was a review of some fragrance oils which got me to thinking that I should do a review of Peak Candle Supply's Birds of Paradise fragrance oil since there had not been any note of one on the spread sheet that the forum had for Peak's fragrances. The scent had been rather flowery and sweet coming out of the bottle. Not my usual fragrances, but I had bought the fragrance for my partner.

I had not noticed that the fragrance had caused ricing or acceleration in making the soap, but I had noticed that the fragrance seemed less noticeable after mixing it. I wanted to check and see how my soap smelled after it had settled a bit and see how the scent seemed to me now so I went over to the bookshelf that serves as a curing rack (it shares the space with the books, of which there are many) and looked for my nice creamy colored soap. I looked where I thought I had put it and then looked around and could not find my nice creamy colored soap anywhere.

I then looked back to where I had thought I had put it to find the dark brown soap that had not been there the night before. It was then it dawned on me that my fragrance oil had vanilla in it and it had discolored my soap to this dark brown. So much for the creamy whiteness that I had been envisioning for my first salt bar.

Anyways, I wanted to post a picture of how the soap had morphed overnight and show how the wonders of vanilla can change a nice, innocent, creamy looking bar of soap and change it forever in just one night!

I had not noticed that the fragrance had caused ricing or acceleration in making the soap, but I had noticed that the fragrance seemed less noticeable after mixing it. I wanted to check and see how my soap smelled after it had settled a bit and see how the scent seemed to me now so I went over to the bookshelf that serves as a curing rack (it shares the space with the books, of which there are many) and looked for my nice creamy colored soap. I looked where I thought I had put it and then looked around and could not find my nice creamy colored soap anywhere.

I then looked back to where I had thought I had put it to find the dark brown soap that had not been there the night before. It was then it dawned on me that my fragrance oil had vanilla in it and it had discolored my soap to this dark brown. So much for the creamy whiteness that I had been envisioning for my first salt bar.

Anyways, I wanted to post a picture of how the soap had morphed overnight and show how the wonders of vanilla can change a nice, innocent, creamy looking bar of soap and change it forever in just one night!

Wednesday, April 10, 2013

Today's Project

Well, most things are still new to me with soap making, but rather then a new technique, I did a new recipe today. Instead of making my regular soap, I made a salt bar of soap. I had been reading a lot on salt bars and was curious about it and my partner said he was interested in having some salt bars, so it seemed like a good excuse.

My recipe is made with 90% coconut oil, 5% castor oil, and 5% Shea butter. At a light trace, I added 75% the weight of the oils to the batter. I had heard that adding the salt would greatly increase the speed of trace, but was a bit surprised when it didn't happen. The salt did increase the general thickness of the batter, but not the consistency. I hope that made some sense. I had added my fragrance oil before I mixed my lye in again, so I had no worries about not being able to pour it into the mold on time. In fact, it was worrying me a bit because it was still pretty liquid going into the mold.

The other warning that I had read was that it needed to be taken out of the mold and cut after a couple of hours instead of being left for 24 hours like a more normal soap. I started checking it after about an hour, and then I unmolded it after an hour and a half. I was worried that it might give me trouble as I used a PVC mold and I feared it would get stuck, but it came out easy enough once I got it started. Cutting this soap was a bit more adventurous then I would have liked because it was very crumbly, but this was not really a surprise.

So, in the end, because it was fairly crumbly, it does not have the nice clean cut that I would like to see in a soap, but I think I will be able to clean it up a little bit after it cures. My other option is to not worry about the fact that it is not the neatest after being cut and next time see if I can use individual loaf molds like many people on the forum do.